Dry Polishing Pads vs. Wet Polishing Pads: Key Differences and Which One to Choose

When it comes to surface polishing, especially in industries like flooring, granite, and concrete, choosing the right polishing pad is essential for achieving a smooth and high-quality finish. Two of the most commonly used types of polishing pads are dry polishing pads and wet polishing pads. Though both are designed to achieve a polished surface, they work in different ways and are suited for different applications. Here’s a breakdown of the key differences between dry and wet polishing pads to help you make an informed decision.

1. Polishing Process: Dry vs. Wet

Dry Polishing Pads

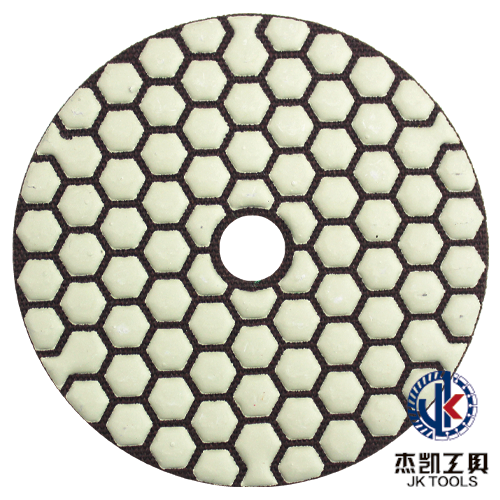

As the name suggests, dry polishing pads are used without any water. They rely on friction and heat to polish the surface. These pads are often used for light polishing or in environments where water might cause damage to the material being polished. The dry process generates more heat, so it is important to manage the temperature to prevent overheating the surface.Wet Polishing Pads

Wet polishing pads, on the other hand, require water to lubricate the surface during polishing. The water helps reduce friction, cools down the pad, and prevents the surface from overheating. This method is typically used for heavier polishing, as the water allows for a finer finish and a more consistent result. Wet polishing is more common in stone, granite, and concrete polishing.

2. Applications: When to Use Each Pad

Dry Polishing Pads

Dry pads are commonly used for polishing materials like marble, granite, and concrete in situations where water usage is not practical or desired. They are perfect for quick, on-the-go polishing and are especially useful for tasks such as restoring or buffing surfaces. Dry pads are also ideal for polishing in areas where moisture could damage the surface or cause safety concerns.Wet Polishing Pads

Wet polishing pads are typically preferred for heavier-duty polishing tasks where a high gloss finish is required. They are used in the stone industry to polish granite, marble, or quartz, as the water cools the material and prevents dust from forming. Wet polishing is also the method of choice when achieving a uniform finish is crucial, such as for intricate surface work.

3. Durability and Finish Quality

Dry Polishing Pads

While dry pads can be convenient and efficient, they may not deliver the same level of smoothness or high gloss as wet pads. The absence of water means that the polishing process generates more heat, which can wear the pads down more quickly and might lead to uneven polishing if not carefully controlled. However, they are more portable and faster for quick touch-ups or lighter polishing jobs.Wet Polishing Pads

Wet polishing pads tend to provide a finer, more polished finish due to the cooling and lubrication provided by water. The water helps prevent the build-up of heat, which can cause the material to become discolored or damaged. Wet pads are also generally more durable, especially when used with harder materials, as they help to dissipate the heat generated during the polishing process.

4. Dust and Cleanliness

Dry Polishing Pads

One of the biggest downsides of dry polishing is the amount of dust it generates. Without water to keep the dust down, dry polishing can create a lot of airborne particles, which may not only be hazardous to health but also create a mess in the work environment. Proper dust extraction is crucial when using dry pads to avoid health risks and maintain a clean working space.Wet Polishing Pads

Wet polishing pads minimize dust generation because the water helps bind the dust particles. The wet method also helps keep the workspace cleaner and safer. However, using wet pads means you need to manage the water and clean up the wet areas, which may require additional preparation and cleanup time.

5. Efficiency and Speed

Dry Polishing Pads

Dry polishing tends to be quicker as it doesn’t require water setup, making it a preferred choice for mobile or on-site polishing tasks. However, it may require more effort and time to achieve the same level of finish that wet pads can provide in one step.

Wet Polishing Pads

Diamond Wet polishing pads are generally slower compared to dry pads due to the time needed to manage water and clean up the work area. However, the overall finish is typically better and more consistent, making wet pads ideal for jobs that demand a high level of precision and a fine, glossy surface.

Conclusion

Both dry polishing pads and wet polishing pads have their own advantages and drawbacks. The choice between the two largely depends on the specific requirements of your project, the materials you’re working with, and your desired outcome. If you're looking for convenience, speed, and portability, dry polishing pads might be the way to go. However, for a smoother, high-quality finish with less heat buildup and dust, wet polishing pads are generally the better choice. Understanding the differences between the two will help you select the right tool for your polishing needs, ensuring you get the best results for your surfaces.